Kaizen is a Japanese term which means 'continuous improvement': this is our ambition!

Our innovative method helps your company to improve management and operational processes, in the continuous search for excellence. BDC 28, thanks to the organizational consultancy focused on the improvement and optimization of business processes, simplifies the management of activities. Find out now how to start a 360 ° collaboration project within the company to increase the coordination of all the phases involved in the production cycle.

Technologies have evolved, laws are changing, responsibilities are changing and competitiveness is even greater. Today, more than ever, companies are called upon to ensure that each organizational unit improves its performance. Keeping the company steps ahead with evolution must be one of the cornerstones at the basis of better business management.

Furthermore BDC 28, thanks to twenty years of experience in the sector, is able to offer specialized consultancy in the field of distribution and warehouse logistics and the supply chain, offering integrated and tailor-made solutions, built on the basis of specific customer needs.

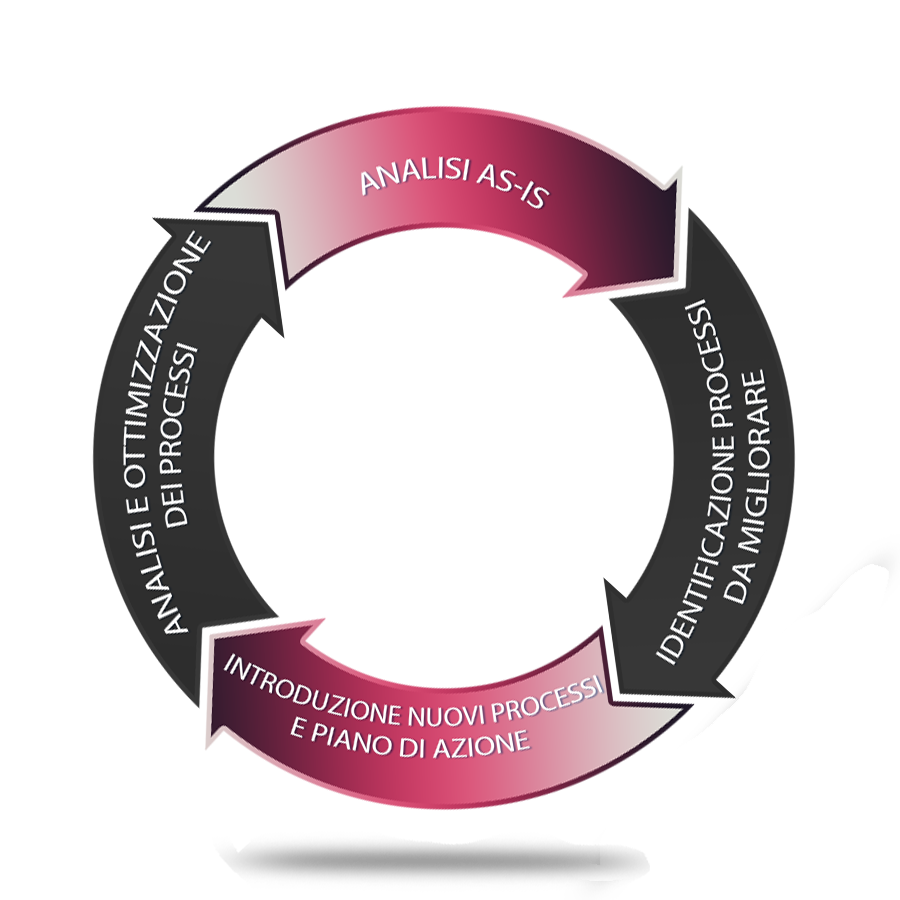

In this phase, the analysis and understanding of the company processes currently in force takes place. For a complete process mapping activity, BCD 28 asks the key questions to be able to understand in detail how these take place within the company and how the process managers operate to achieve their daily goals. This phase takes place the analysis and understanding of the company processes currently in force. This phase is fundamental as it lays the foundations for the creation of the documentation necessary for the future intervention plan.

Following the mapping of a company's existing processes, it is essential to identify the areas and processes, in line with the strategic objectives, on which to focus in order to improve the efficiency of the business. In this phase, the performance indicators (Key Performance Indicators) are prepared to make these processes defined and measurable. It should be noted that even if the mapping phase concerns the entire company reality, the areas of improvement intervention, at first, can only take place on some key processes for the company strategy pursued. Focusing your efforts on strategic processes is the key to making your customers perceive more value and consequently, the fastest way to achieve business objectives.

In this phase, the new business processes are modeled and designed with a view to greater integration. The new processes, including the steps to be taken and the reference times to achieve the improvement objectives set, are shared with the stakeholders and improved up to the final version which will be illustrated to the relevant operational managers. This last step is very delicate as the activities that make up a process can also belong to multiple company functions.

The introduction of the new processes in the company involves the measurement and verification of the results obtained. These analyzes are the key to continuous business improvement and to increase the efficiency of each resource involved in the process. This results are a continuous measurement of the processes and their improvement. In this way, a high quality of service is guaranteed in all its phases, the continuous improvement of the company and the effective achievement of the objectives initially established.